Helmets are crucial protective gear used in a variety of settings, including construction sites, industrial environments, motorcycling, sports, and more. In India, ensuring the safety and quality of helmets is paramount, which is why the Bureau of Indian Standards (BIS) sets stringent guidelines for helmets used in different sectors. Helmets meeting BIS standards are designed to provide maximum protection to the wearer, preventing or minimizing head injuries in case of an accident or impact. This article delves into the significance of helmets meeting BIS standards, their key features, and why compliance with these standards is critical for safety.

What are BIS Standards?

The Bureau of Indian Standards (BIS) is the national standard body of India, responsible for setting standards across various products and services. BIS standards are developed to ensure the safety, reliability, and quality of products, including helmets. For helmets, these standards cover the design, materials, performance, testing, and labeling, ensuring that helmets deliver the protection they are intended for.

BIS standards for helmets are set under the IS 2925:1984 for industrial helmets and IS 4151:2015 for protective helmets used in two-wheeled vehicles. These standards aim to ensure that helmets provide adequate protection against impact, penetration, and other potential hazards.

Key Features of Helmets Meeting BIS Standards

- Impact Resistance

Helmets meeting BIS standards must be capable of withstanding significant impact forces. The outer shell of the helmet is made from durable materials, such as fiberglass or high-density polyethylene, which are engineered to absorb and dissipate the energy from an impact. This ensures that the force exerted on the head during a collision or fall is minimized, reducing the risk of serious injury.

- Penetration Resistance

One of the critical tests for helmets meeting BIS standards is their ability to prevent sharp objects from penetrating the helmet. The outer shell of the helmet is designed to resist penetration from objects such as nails, sharp debris, or other pointed items that might pose a risk in hazardous environments. This feature is especially important in construction sites, industrial workplaces, and other high-risk areas.

- Shock Absorption

In addition to impact resistance, BIS-compliant helmets are tested for their ability to absorb shock. Inside the helmet, there is typically an energy-absorbing foam or padding, such as expanded polystyrene (EPS), that cushions the head from the impact forces. This padding helps to reduce the force transmitted to the skull and brain, minimizing the potential for concussions and other serious injuries.

- Strap System and Retention

A helmet is only effective if it stays securely on the head during an impact. BIS standards ensure that helmets are equipped with an effective strap and retention system to keep the helmet in place. The chin strap, typically adjustable, ensures a snug fit, and the retention system prevents the helmet from dislodging during a fall or accident.

- Ventilation and Comfort

While safety is the primary concern, helmets meeting BIS standards also account for comfort. Proper ventilation is an important feature, especially for helmets worn for extended periods. Vents and air channels in the design help reduce heat buildup inside the helmet, ensuring the wearer remains cool and comfortable.

- Design and Visibility

BIS standards also ensure that helmets are designed for maximum visibility. For workers in construction, traffic officers, or cyclists, helmets often come with reflective tapes or bright colors to enhance visibility in low-light conditions. The design also includes consideration for comfort and ease of use, ensuring that the helmet does not obstruct vision or hearing.

Compliance with BIS Standards: Why It Matters

- Ensuring Safety

The most crucial reason for helmets meeting BIS standards is safety. Helmets are designed to protect the most vital part of the body—the head. In the event of a fall, accident, or collision, a helmet that meets BIS standards can mean the difference between life and death. These standards ensure that the helmet offers adequate protection against various types of injuries, from skull fractures to brain damage.

- Legal Compliance

In many industries, using helmets that meet BIS standards is not just a recommendation but a legal requirement. For example, workers in industrial and construction sectors are mandated to wear BIS-approved helmets to comply with safety regulations. Failure to adhere to these standards can lead to legal consequences for both employers and individuals.

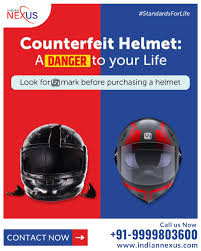

- Quality Assurance

BIS standards guarantee the quality and reliability of helmets. When purchasing a helmet that meets these standards, consumers can be confident that the product has undergone rigorous testing and is manufactured to high-quality specifications. This ensures that the helmet will perform as expected in the event of an accident, reducing the risk of injury.

- Product Durability

Helmets that meet BIS standards are built to last. The materials used in the construction of the helmet are durable and resistant to wear and tear, ensuring that the helmet remains effective over time. This long-term durability means that the helmet will continue to offer protection for its entire lifespan, provided it is maintained and used properly.

- Increased Confidence and Trust

When a helmet meets BIS standards, it not only assures the wearer of their safety but also builds trust with employers, customers, and the general public. For businesses, using BIS-approved helmets demonstrates a commitment to worker safety and compliance with industry regulations. For consumers, purchasing a helmet that meets these standards provides peace of mind, knowing they are using a high-quality, reliable product.

How Are Helmets Tested for BIS Standards?

Helmets undergo several tests to ensure they meet BIS standards. These tests include:

- Impact Test: Helmets are subjected to controlled impacts at various points to ensure they can absorb and dissipate energy effectively.

- Penetration Test: A sharp object is dropped onto the helmet to check its resistance to penetration.

- Retention Test: The chin strap and retention system are tested to ensure that the helmet remains securely in place during impact.

- Vibration and Comfort Test: Helmets are tested for comfort and proper fit, ensuring that they do not cause discomfort during prolonged use.

- Visual Inspection: The helmet is examined for any visible defects, such as cracks, weak spots, or manufacturing defects that could affect performance.

Conclusion

Helmets meeting BIS standards are essential for providing effective head protection in various environments. From construction sites to roadways, these helmets are designed with key features like impact resistance, penetration resistance, shock absorption, and a secure retention system. Compliance with BIS standards ensures that helmets are of high quality, safe, durable, and legally compliant. By choosing helmets that meet these standards, individuals and businesses can prioritize safety and mitigate the risk of head injuries. As the demand for safety gear continues to rise, it is critical to stay informed about the standards that govern helmet safety and ensure that the products we use meet these essential criteria.